At K’ 2022, ENGEL booth showed a giant leap for the packaging industry: Ultrathin-walled PET cups containing 30% of recycled PET can be produced directly in injection molding in less than 3 seconds already labelled. This Austrian injection machine manufacturer has processed during the K a mixture of 70% PET resin Novapet SPRIT B21 and 30% of recycled PET (rPET) on its booth.

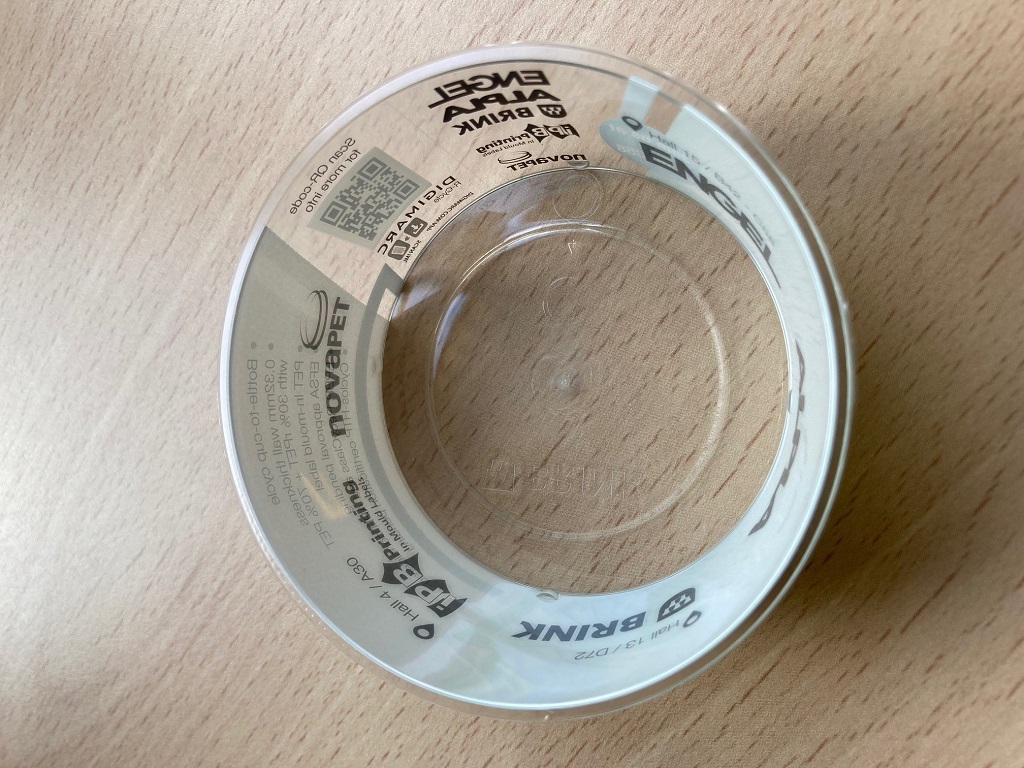

The cup with a wall thickness of 0.32 mm and a net volume of 125 ml impressed all the visitors, especially those from the food industry, as thanks to integrated in-mold labeling (IML), the containers leave the production cell ready to be filled in cycles of 2,8 seconds!

Up to date, post consumption rPET is so far the only plastic that can be processed back into food packaging. This significantly expands the range of uses for PET and rPET. In addition to the bottle-to-bottle cycle, the establishment of bottle-to-cup or even cup-to-bottle recycling is also possible.

SPRIT B21 is a PET resin produced by Novapet (Barbastro, Spain) developped for ultrathin-walled injected packaging. Convertor ALPLA (Hardt, Austria) has supplied the rPET, tooling manufacturer Brink (Harskamp, The Netherlands) has supplied the mold and IML automation e IPB Printing (Reusel, Países Bajos) have supplied the PET IML lables.