According to a recent report from the Imperial College of London, plastics do have a large carbon impact accounting for 3.8% of global greenhouse gases emissions, but it is wrong to assume that alternative packaging materials would perform better, and it is important to consider the carbon benefits that arise from plastics use. Results can vary significantly from one study to another, depending on key parameters and assumptions. For example, the risk of producing more food waste because of the packaging design and shelf life is not always considered in life cycle assesments (LCAs).

In the study we share today, a total of 73 publications on LCAs comparing different types of packaging were identified and reviewed. Findings indicate that in the applications it is used, most of the time, plastic packaging performs better than its alternatives, and mainly due to its very lightweight properties.

Transport distance and method, sources of electricity generation, packaging shape and weight, all significantly influence the LCA results and should be considered on a case by case basis.

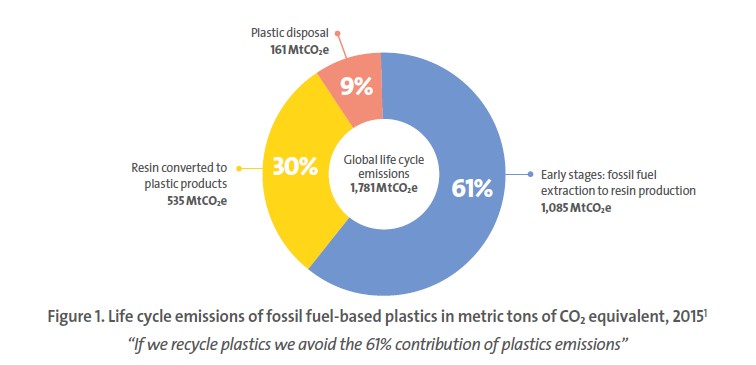

The overwhelming majority of plastic resins come from petroleum, which requires extraction and distillation. Then the resins are formed into products and transported to market. All of these processes emit greenhouse gases, either directly or via the energy required to undertake them. The carbon footprint of plastics continues after their end of life, since landfilling, incinerating, recycling and composting (for certain plastics).

Looking at the entire life cycle of fossil fuel-based plastics today, nearly two thirds of its greenhouse gas emissions are produced in the early stages from fossil fuel extractions to the production of resin, while converting resin to pipes, bottles, bags and other products generates just under one third of its emissions. This indicates there are high carbon benefits of recycling plastics, avoiding those 61% of greenhouse gases emissions from the extraction and resin production process.

Despite the large impact of plastics on the environment, their application for packaging offers some environmental benefits:

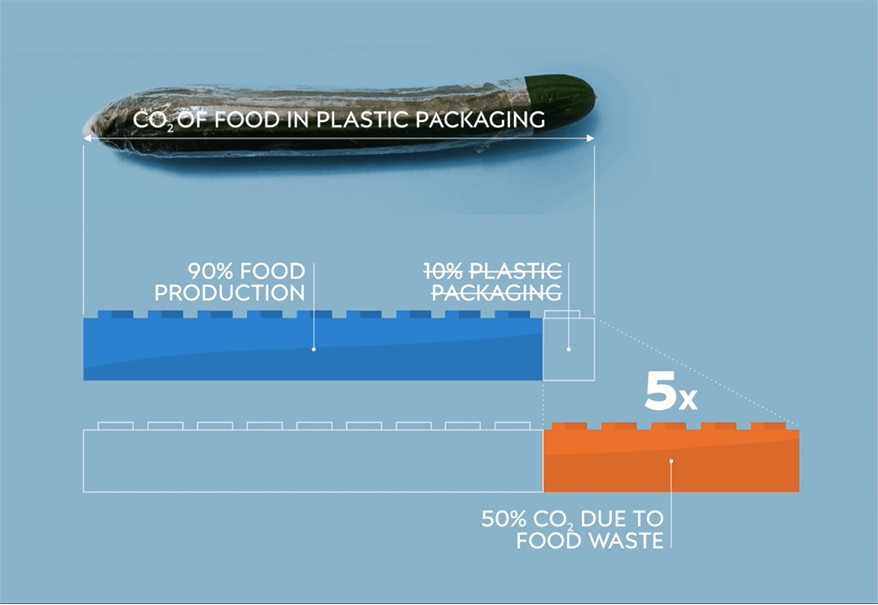

- Plastic is a versatile material which can easily be made thin and lightweight. It is durable and provides protection from contaminants and the elements. It reduces food waste by preserving food and increasing its shelf life. It protects food against pests, pathogens and humidity. Plastic packaging is more flexible and lighter than alternatives such as glass and card, which reduces transportation costs and the carbon emissions that come with them.

- Without packaging, food is more likely to get damaged and become unusable. Since food waste contributes to climate change, water and energy consumption, deforestation and biodiversity loss, every effort we make to mitigate those effects makes a big difference, and plastic packaging helps make that possible.

- Plastic packaging is useful for keeping products fresh and insulated. Removing plastic entirely from our food supply may not be the best solution when it comes to protecting the environment and conserving valuable resources. Plastic packaging is used in the food supply chain because it supports the safe distribution of food over long distances and minimises food waste by keeping food fresh for longer. For example, the use of just 1.5g of plastic film for wrapping a cucumber can extend its shelf life from three days to 14 days and selling grapes in plastic bags or trays has reduced in-store wastage of grapes by 20%.

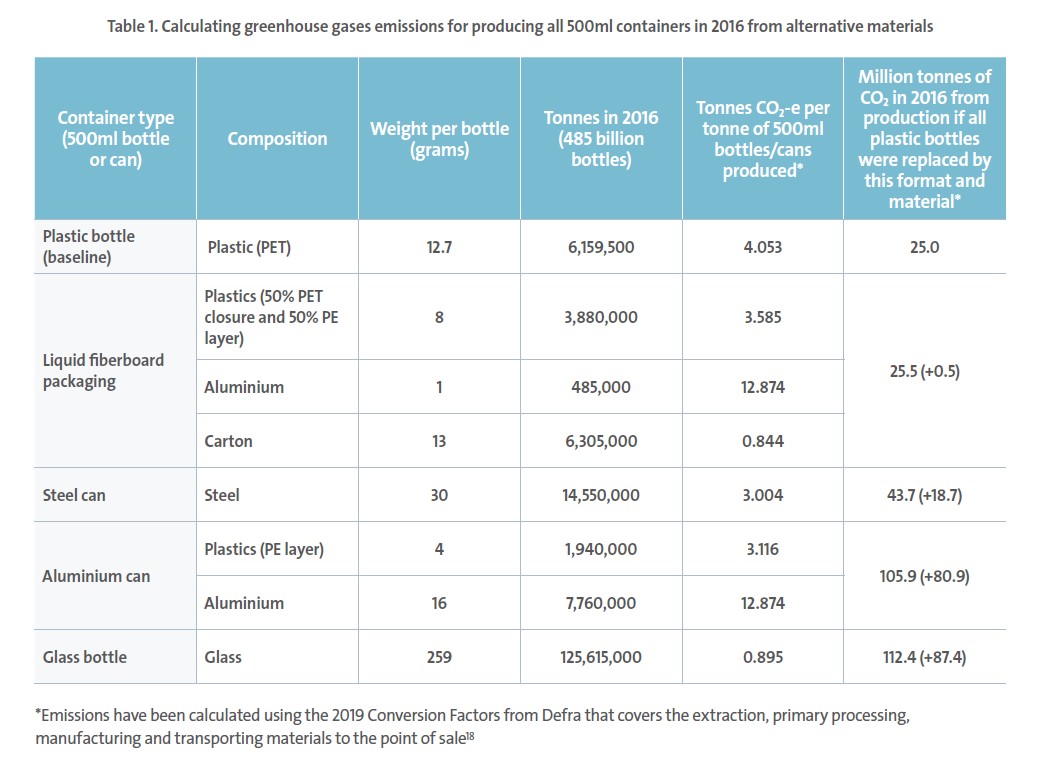

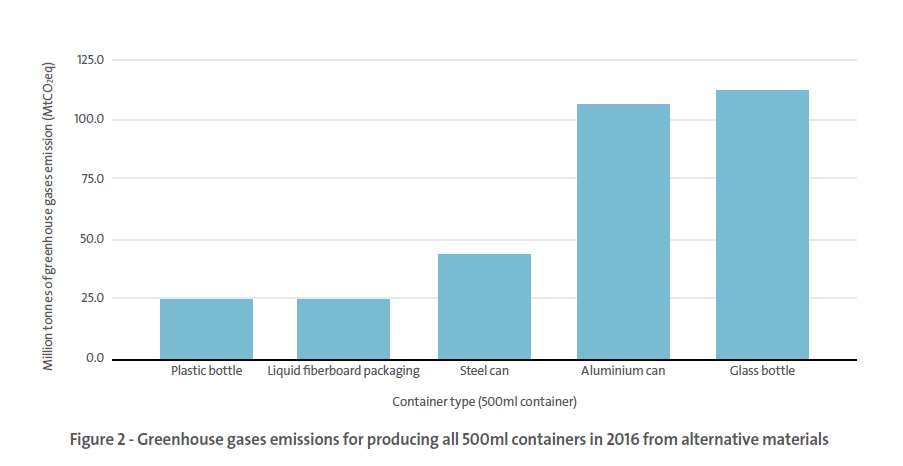

The carbon impact of plastic bottles compared to other material type containers

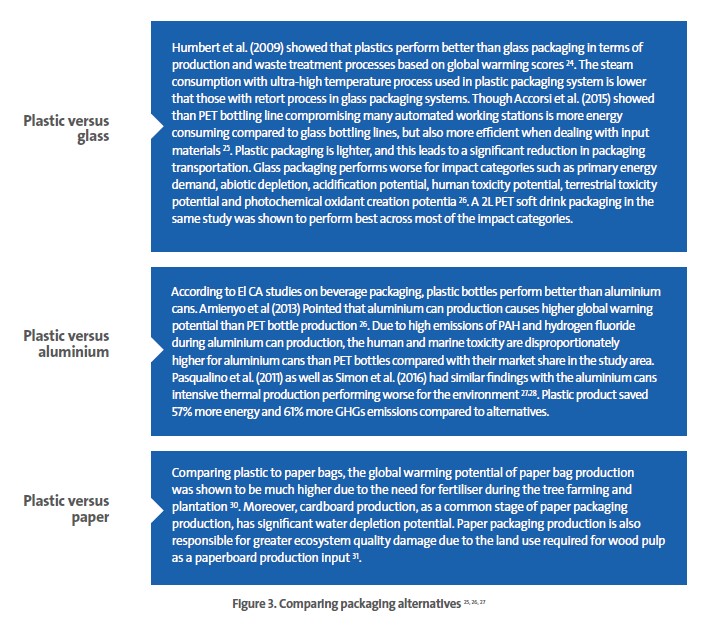

All food and drink packaging, whether plastic or another material, has an environmental impact. There is a lot of emphasis on plastic waste and pollution, but other impacts such as carbon emissions must also be considered when determining which materials are most suitable for different packaging applications. When considering reductions in the use of plastics, it is therefore important to consider the carbon footprint of things that could replace plastic, materials such as paper, aluminium, or glass.

It is also worth noting that aluminium cans and carton containers, despite often being explicitly depicted as alternatives to plastic bottles, still contain considerable amounts of plastic. Aluminium cans often have a complex plastic closure weighing around 4g (nearly half the weight of a single use plastic bottle); glass containers usually include a relatively heavy plastic lid – 14g (meaning they weigh more than a lightweight plastic water bottle); and multilayer cartons usually include nearly 10g of plastic (roughly the weight of a plastic water bottle). In addition, virtually all metal cans used for food and beverage products are also lined on the inside with a coating that uses Bisphenol A (BPA) as a base protective material, while most plastic bottles are made from polyethylene terephthalate (PET) plastic, which does not contain BPA.

To illustrate the difference of carbon impacts from the production of bottles from plastics and alternative materials, we calculated carbon emissions that would have been incurred in 2016 if every 500ml PET bottle produced worldwide was replaced by alternative material. The results are shown in Table 1 and Figure 2.

Life cycle assessment (LCA)

Life cycle thinking is increasingly seen as a key concept for ensuring the sustainability of resources production and consumption. Over the years, life cycle assessment has been used extensively to assess products from “cradle to grave” from extraction of resources to end of life management.

The assessment has been formalized by the International Standard Organization (ISO) in Geneva, Switzerland. LCA is based on an iterative process with four steps, i.e., goal and scope definition, inventory analysis, impact assessment, and interpretation.

LCA provides a quantified methodology to assess the environmental performance of goods and processes. The LCA study usually starts with raw material extraction and ends with the final products leaving the factory gate. A cradle-tograve study starts with raw material extraction and ends with the disposal of product in landfill, incineration or recycling. A cradle-tocradle study starts with the same process and considers not only the final disposal but also the energy recovery from incineration or the raw material replacement due to recycling of the studied products.

Most LCA undertaken for various plastic uses show plastic performing better than the alternatives from a carbon perspective. Even if, ounce for ounce, some kinds of plastic have a higher carbon footprint than other kinds of packaging, less quantity is used reducing overall impact, as plastic is light. Plastic performs better most of the time (for example heavier-duty plastics, such as low density polyethylene or woven polypropylene bags, do have a bigger climate and energy impact than paper, but they’re more durable and you get more use out of them). Several studies have shown many materials used as alternatives to plastic in packaging, such as cotton, glass, metal or bioplastics, to have significantly higher CO2 impact or water usage compared to plastic packaging.

Importance of recycling

Recycling always wins over virgin production on all environmental indicators. For plastics, there seems to be consensus that recycling saves between 30% and 80% of the carbon emissions that virgin plastic processing and manufacturing generate.

If all plastic were recycled this could result in mean annual savings of 30 to 150 million tonnes of CO2, equivalent to stopping between 8 and 40 coal-fired power plants globally.

Considering that only around 9% of plastics are currently being recycled worldwide, there is a lot that can be done to improve things.

Increasing the recycling of plastics have the potential for:

- Curbing the growing life-cycle GHG emissions from plastics.

- Preventing them from entering the marine environment.

Some LCAs maintain the assumption that all products are collected, recycled, and reused in the end-of-life phase. The reality, however, is not that simple; and often depends on recycling rate in a particular study/country/city. End of life scenario has a great impact on the LCA results and on what can be done to reduce impacts. In many studies it is demonstrated that the systems of recycling of PET containers in closed circuits work very well, receiving a high rate of recycled PET.